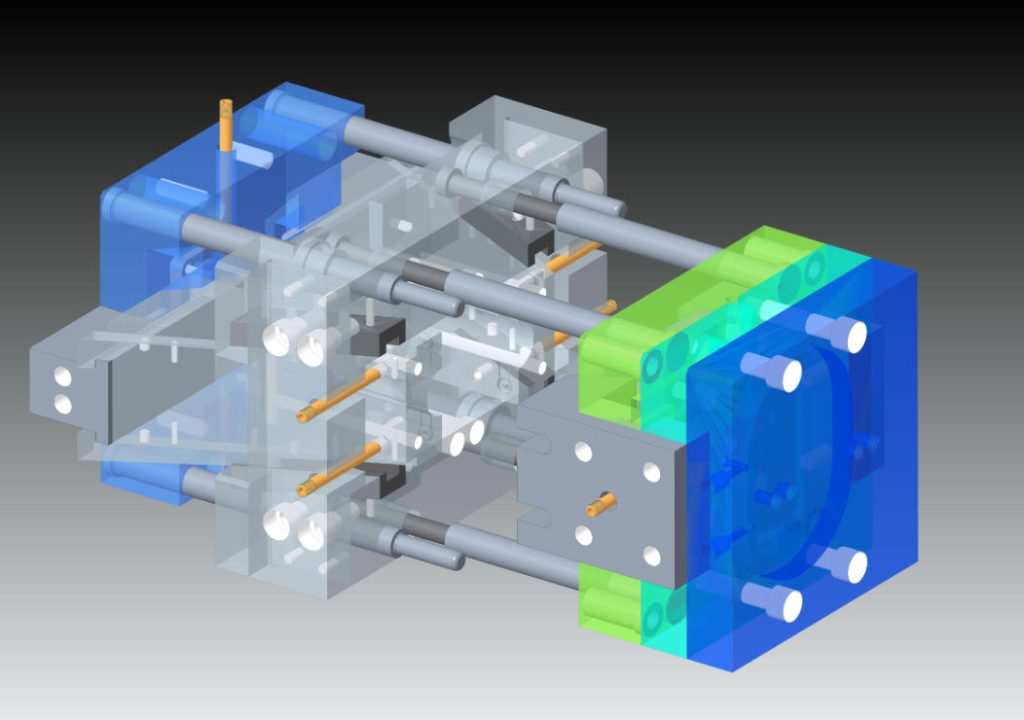

By utilizing our talented in-house team of designers, we can efficiently produce molds tailored to your exact needs. Our capabilities span from simple single-cavity to complex multi-cavity molds. We employ hot-runner systems to achieve precise tolerances, improve design flexibility, and deliver top-notch products. This method brings benefits like reduced injection pressures, minimized material waste, and shorter cycle times.

Injection Mold Design Service Benefits

Bruin Manufacturing can help you gain a competitive advantage in the manufacture of injection-molded plastic parts and assemblies with innovative mold design services for orders we manufacture. From simple open-and-shut molds to complex multi-cavity designs, we develop exceptional solutions that deliver:

- Enhanced profitability

- Improved efficiency

- Design bottleneck elimination

- Reduced expenses

- Boosted productivity

- Unmatched accuracy

- Improved automation

Plastic Injection Molding Design Services

We have a team of highly trained engineers with many years of combined experience designing molds that are high performing, cost-effective, and simple to manufacture. Innovative Creo modeling software enables us to view and work with your print or 3D CAD file in various formats. Plans are carefully reviewed, and a variety of factors are considered to determine the best possible mold design. Examples include:

- Aesthetics

- Cycle time optimization

- Wall thickness uniformity

- Cosmetic challenges

- Stress

- Proper draft

- Shrinkage

- Dimensional stability

At Bruin Manufacturing, we specialize in the design of molds that minimize the need for human intervention, which reduces costs while increasing productivity. Our team can work with yours to develop molds that perform multiple actions or self-assemble as they open.

Whether you have an idea but no drawing in hand or an established design that can be optimized, Bruin Manufacturing is in your corner.

Contact us to learn more about our mold design services.

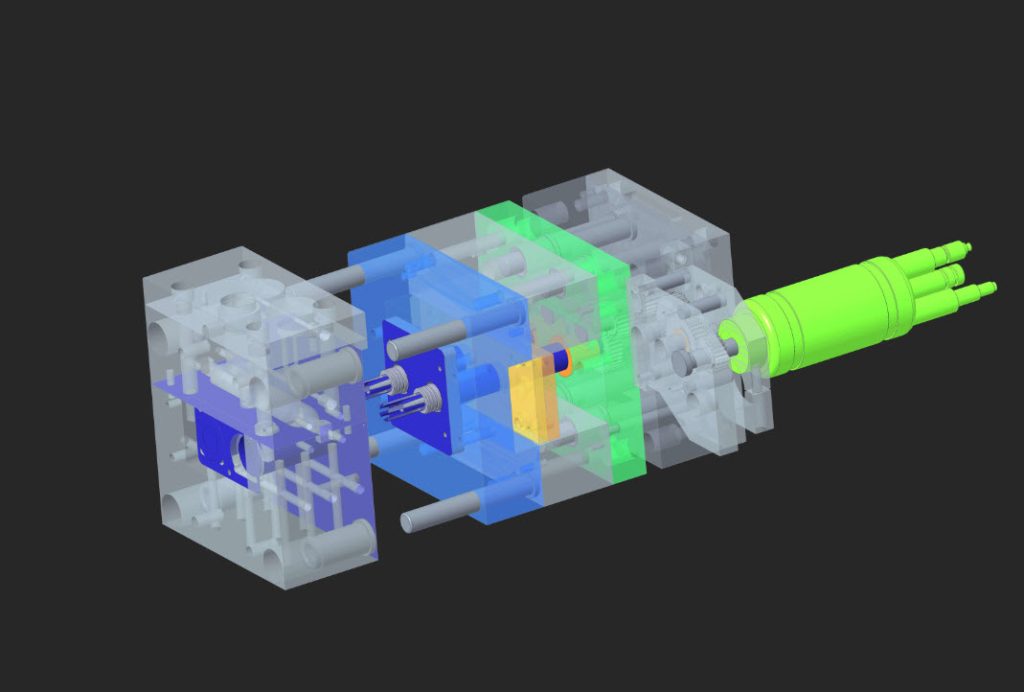

Injection Molding Prototypes

A primary concern for any manufacturer is confirming the products they bring to market are optimally designed, aesthetically pleasing and functional. Confirm the plastic components or assemblies your design produces perform as intended with high-quality prototyping services from Bruin Manufacturing.

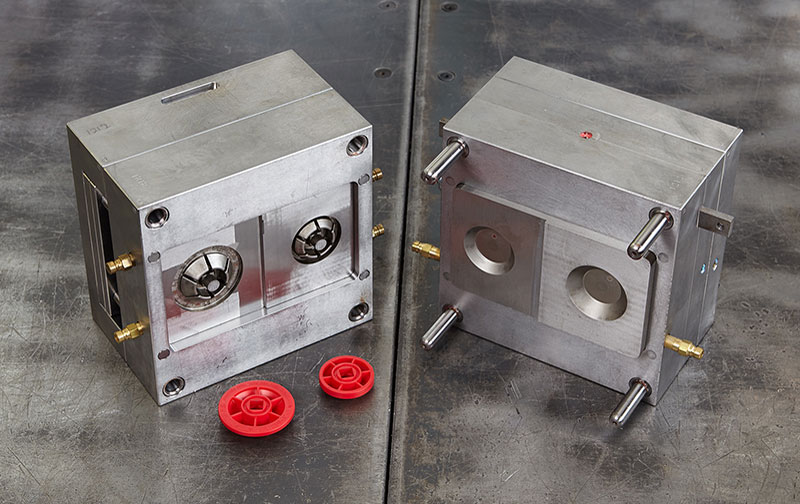

Bruin hot runner prototype/bridge mold base with changeable prototype inserts.

Prototype Plastic Injection Molding Services

We are a full-service plastic injection molder specializing in the in-house development of affordable tooling used to produce prototypes, one-offs, and low-volume pieces. This process enables our customers to inspect, test and scrutinize finished products, tweaking and resolving all details to ensure the best possible outcome, without the high cost of a full production run.

There are many reasons to prototype before starting full-scale production. Examples include:

- Quality assurance purposes

- When significant testing or proving is required

- Consumer research

- Show buyers a finished part instead of a sketch, drawing, or rendering

Injection Molding Prototype Quality

Deciding to prototype doesn’t have to mean lower quality. At Bruin Manufacturing, our prototype molds are made from the same high-quality steels as standard production ones. Mold bases are manufactured from lightweight but corrosion-resistant stainless steel. Hardened tool steel inserts and cores provide robust strength.

When you are ready to begin full-scale manufacturing, we can produce from the prototype die while the full production mold is built. Our approach offers the following benefits:

- Shortens lead times

- Shortens lead times

- Reduces costs

Customers seeking orders of more than a few thousand cycles are encouraged to move away from prototype dies and toward standard molds, which can withstand faster cycle times and higher production levels. Every standard mold we fabricate adheres to the Society of Plastics Industry’s Class 101 standard.

Injection-molded prototypes can be very beneficial to making a successful product. It enables you to verify part engineering, display a finished product or eliminate imperfections before investing in mass production. With Bruin Manufacturing, we can help you get there.

For more information about our prototyping services, contact our team.

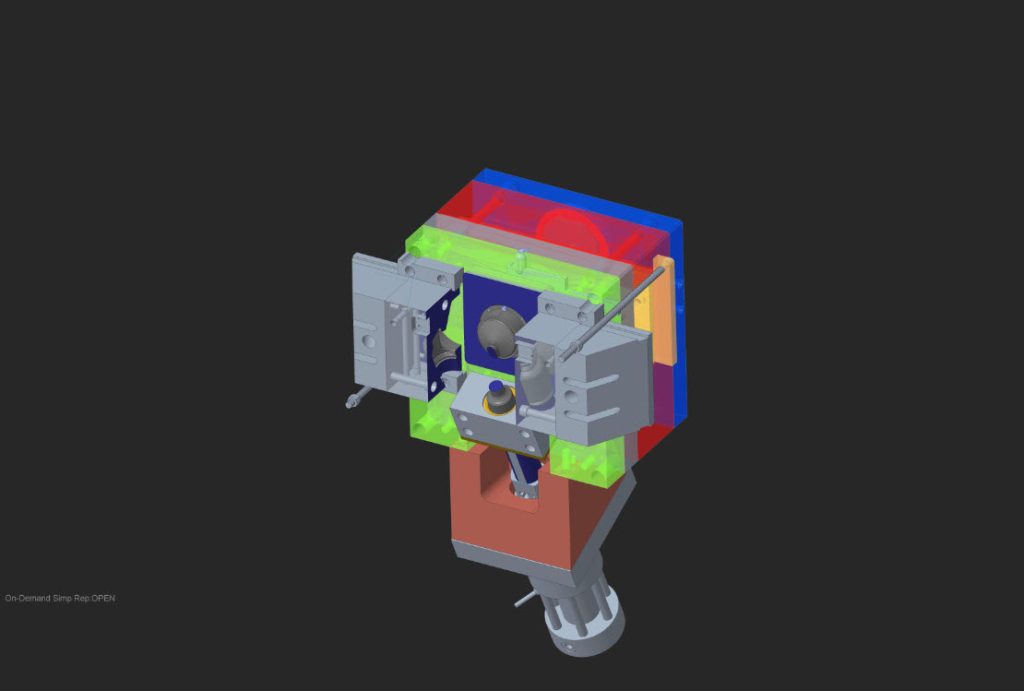

Machine Design for Injection Molding

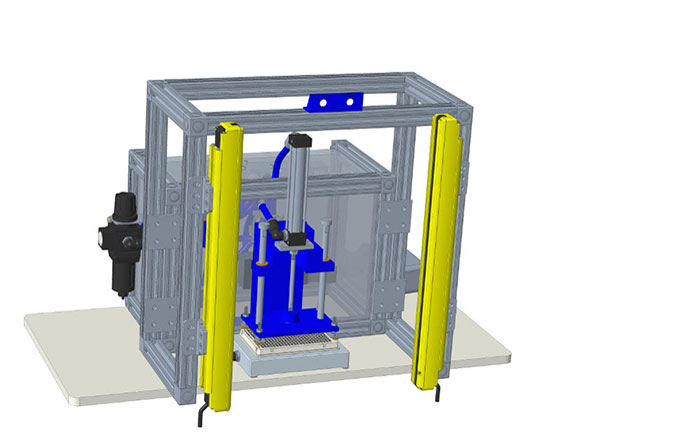

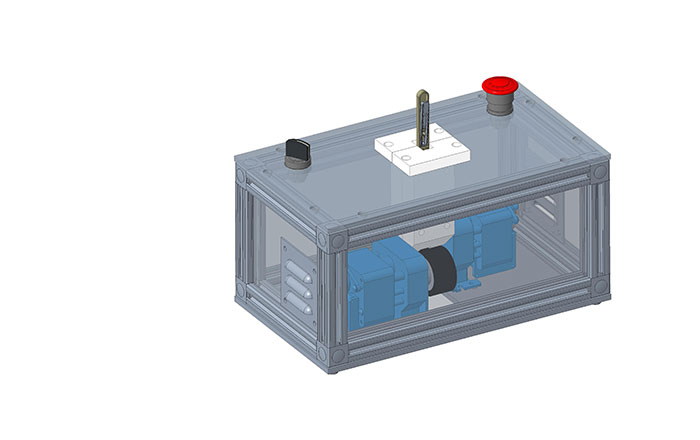

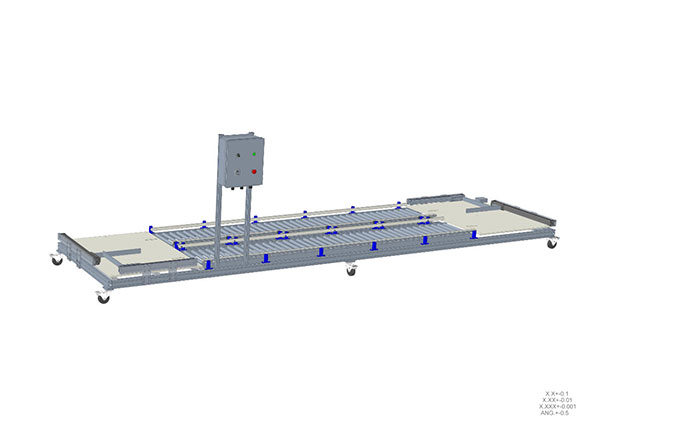

Manufacturing precision plastic parts and assemblies often involve more than merely extruding or injection molding. A completed product or device typically requires various secondary operations to function correctly. That’s why Bruin Manufacturing’s in-house team specializes in the development of machines tailored to optimize client orders, streamlining the plastic injection part or assembly molding process.

Machine Design Capabilities

Examples of tasks our custom-designed plastic injection molding machines can perform include:

- Assembly

- Retrieval

- In-process and finished product movement

- Packaging preparation

- Quality checks

- Stacking

- Sorting

Improper planning of secondary operations can increase production costs and time. If secondary operations aren’t considered up-front, processes will suffer, and expectations will be missed. As a plastic injection molding leader, Bruin Manufacturing understands the importance of producing high-quality parts and assemblies on time and within budget.

Machine Design Benefits

Our custom-designed machines for plastic injection molded parts offer the following benefits:

- Unmatched quality

- Lower costs

- Bottom-line cost savings

- Improved efficiency

- Reduction or elimination of human intervention

Machine Design for Secondary Processes

Secondary processes are critical to the production of reliable, high-performing plastic-injected components and assemblies. Planning for them from the outset can have a positive impact, and our designers and engineers can work with your team to develop machines that optimize product manufacturing. When this is done, products can be manufactured, assembled, and packaged in a continuous flow with minimal or no disruption, which can help lower costs and increase efficiency.

Fully automatic molding machines designed and built by Bruin in 1964 and still running!

First Ever Bruin Built Machine

FAMILY OWNED PLASTIC INJECTION MOLDING COMPANY

Headquartered in Marshalltown, IA since 1949

At Bruin Manufacturing, we are the small parts problem solvers. We offer total, integrated custom injection molding services that can meet your needs for quality, time, and price.