Automated Plastic Injection Molding

Here at Bruin, we utilize robotics and automation. The benefits of automation include enhanced consistency, faster production, improved quality, reduced expenses, and minimized waste, allowing for precision and quality outside of our regular working hours.

We are ISO 9001 certified and focus on exceeding production expectations.

Injection Molding Automation Streamlined Production

Injection molding is a process used to manufacture products by injecting molten material into a shaped mold. When the injected material cools, it retains the shape of the mold and is removed. At Bruin Manufacturing, we utilize emerging robotics and automation technologies in injection molding process lines to reduce costs and shorten lead times, savings that are happily passed on to our customers.

Manufacturing your plastic products on our automated injection lines offers a variety of advantages. Examples include:

- Improved repeatability

- Decreased cycle times

- Enhanced product quality

- Increased speed to market

- Lower manufacturing costs

- Reduced labor costs

- Lessening of waste and variation

Automation helps make manufacturing more affordable by reducing labor demands. Once the mold is created and processes are finalized, only one operator is needed for control and management. With machines that provide an extremely high degree of precision and quality, production can continue after hours when necessary

Hot-Runner Molding Systems

Bruin Manufacturing utilizes the hot-runner system, which enables our team to meet tight tolerances, offer design flexibility and produce higher quality items than competitors.

In hot-runner systems, the mold is ready to run when the system reaches operating temperature. They enable the use of lower injection pressures, reducing mold and platen deflection and minimizing flash caused by mold component movement.

Hot-runner systems generate better filling and packing conditions than their cold-runner counterparts. When plastic flows through the cold-runner, it loses heat to the mold plates. This can cause pressure drops resulting in sink marks and under-filled parts. Hot-runner systems, however, maintain a balanced melt flow at a constant temperature from the machine nozzle to the gate.

Major advantages to using our hot-runner system include:

- Balanced melt flow

- Elimination of the runner

- Improved molding efficiency

- Capable of producing detailed features and complex geometries

- Reduced cycle time

- Optimal part quality

While hot-runner systems offer a wealth of benefits, they are not suitable for all molding applications. It can be best to keep some parts attached to runners for handling and orientation purposes. We also offer cold-runner services for those designs.

Automated Injection Molding Applications

Production of plastic parts using automated injection molding is quick and affordable. The process is responsible for the creation of products consumers use day in, day out. Examples include:

- Packaging

- Lids

- Containers

- Instruments

- Fasteners

- Caps

- Buckles

Injection Molding Automation Capabilities

The use of collaborative robots in injection molding processes helps improve production of plastic parts both tiny and significant, in small batches to large quantities, with precision, speed, and quality.

Whether you have a design already or need one created, we offer a full suite of services to take a product from idea to production, including:

- Product design

- Material selection

- Ultrasonic welding

- Gain a competitive advantage

- Mold making

- Manual and automated assembly

- Secure, custom packaging

The success of companies relies heavily on supply chain partners. At Bruin Manufacturing, we are dedicated to doing what it takes to meet customer needs on time and within budget.

To learn more about automated injection molding, contact our team.

Injection Molding Automation Capabilities

Small Part Injection Molding

Bruin Manufacturing is an ISO 9001:2015 certified manufacturer and has over 70 years of experience in small-part injection molding. We are a custom injection molding company, and we specialize in those technical, more difficult parts. Bruin offers all services in-house. From help with part design, out to the tool shop, into a molding press and on to packaging and shipping your part out the door, it’s all done in one location! With Bruin’s pioneered “lights out” system, we can meet the tightest tolerances, offer design flexibility and produce items with reduced cycle times and minimal labor content.

Our entire production process is unique. We’ve developed high-output automated process lines capable of fabricating parts with a high degree of precision, accuracy, and consistency with minimal operator oversight. This reduces labor needs, a cost reduction we happily pass along to our customers!

Small Part Injection Molding Capabilities

A “small part” is defined as a part that fits on the palm of one hand while a “micro” part is smaller than a fingernail. The smallest part manufactured by Bruin so far has been 0.05 grams and the smallest tolerance has been less than 1/1000 of an inch. With nearly 60 plastic molding presses with sizes ranging from 25-165 tons, our capabilities include:

- Small batch to large scale production

- Faster production times

- Precision manufacturing

- Flexible design capabilities

- Automated production

- High repeat tolerance

- High-quality end product

Small Part Injection Molding Benefits

Bruin Manufacturing runs 24/6 with just one shift with employees in the plant. The other two shifts are done “lights out” with no employees present. This keeps our labor cost down and therefore, your part price lower. Other benefits of working with Bruin include:

- Lower labor costs per part

- Material and color flexibility

- Minimal scrap

- Engineering expertise and assistance

- In-house tooling

- Mold transfer capability

- Lower part price

- Minimal finishing requirements

- Proven History

- Responsiveness and reliability

- Secondary operation capability

- 2-shot molding

Small Part Injection Molding Applications

Our services can benefit a variety of industries including, but not limited to:

- Construction

- Medical (non-invasive at Bruin)

- Consumer goods

- Agriculture

- Recreational

Bruin Manufacturing Service Capabilities

Bruin Manufacturing is an ISO 9001:2015-certified manufacturer and we offer a full suite of services to take a product from idea to delivery. Our in-house capabilities include:

- Product design

- Mold making

- Manual and automated assembly

- Overmolding, manual & automatic

- Pad Printing

- Mold design

- Material recommendation

- Ultrasonic welding

- Secure, custom packaging

- Heat Staking

Plastic Injection Overmolding Services

It’s hard to deliver finished items to market efficiently and affordably when you manually add layers of elastomeric materials to plastic parts on the shop floor. Optimize your process with overmolding services from Bruin Manufacturing.

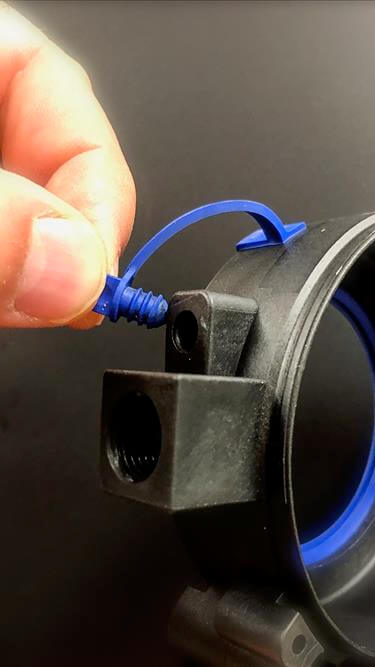

Bruin Manufacturing is a fully integrated plastic injection molding company that specializes in bonding softer layers of materials to structural components for critical applications. From one-off prototypes to large scale production runs, our plastic injection overmolding solutions can improve a part or end product while reducing labor and materials.

Overmolding Benefits

Overmolding is an injection molding technique that combines multiple plastic or elastomeric materials to create versatile, high performance finished products. It’s often used to bond a flexible material with a rigid, structural substrate to enhance functionality, durability, or appearance. Additional advantages include:

- Improved grip or handling

- Greater strength and structure

- Protection against sharp edges or corners

- Increased electrical resistance

- Bolstered ease of use and safety

- Reduced noise and vibration

- Safeguard against water, dust, and contaminates

- Better shock absorbency

Plastic Injection Overmolding Applications

Overmolding Applications

A variety of thermoplastic materials can be overmolded, from soft plastics such as urethanes and thermoplastic elastomers to hard plastics like nylon and polycarbonate. This provides enhanced design flexibility, which benefits an array of industries.

- Construction

- Consumer goods

- Recreation

- Noninvasive medical

- Agriculture

- Agricultural genetics

Commonly called plastic overmolding or elastomeric overmolding, the process is employed to produce a wide range of items. Here are a few examples:

- Cables

- Handles

- Electronic circuits and connectors

- Elastomeric grips or seals

- Custom metal components

- Toothbrushes

- Filters

- Knobs

- Threaded inserts

- Brackets and handles

In many circumstances, overmolding lowers the time and cost necessary to manufacture a part. Molding directly to a component’s surface reduces assembly steps and labor hours.

Overmolding Services

Bruin Manufacturing provides custom plastic injection overmolding for a wide range of demanding applications.

We offer the following services:

- Engineering

- Production and shipping

- Tooling

- Quality assurance

Additionally, our facility operates with a lights out production concept in which production lines operate around the clock. When the mold is created and processes are finalized, only one operator is needed to set up the production run. Once underway, the machines operate unattended. This curbs labor needs, a cost reduction we happily pass along to our customers.

Overmolding Services

Our team will partner with you to develop proper mold design and select the best materials for the job. We have 60 plastic injection molding presses with sizes ranging from 25-165 tons and utilize a pioneering hot runner system that meets the tightest tolerances, offers design flexibility, and produces items with reduced cycle times.

Contact us for more information about our plastic injection overmolding services.

FAMILY OWNED PLASTIC INJECTION MOLDING COMPANY

Headquartered in Marshalltown, IA since 1949

At Bruin Manufacturing, we are the small parts problem solvers. We offer total, integrated custom injection molding services that can meet your needs for quality, time, and price.